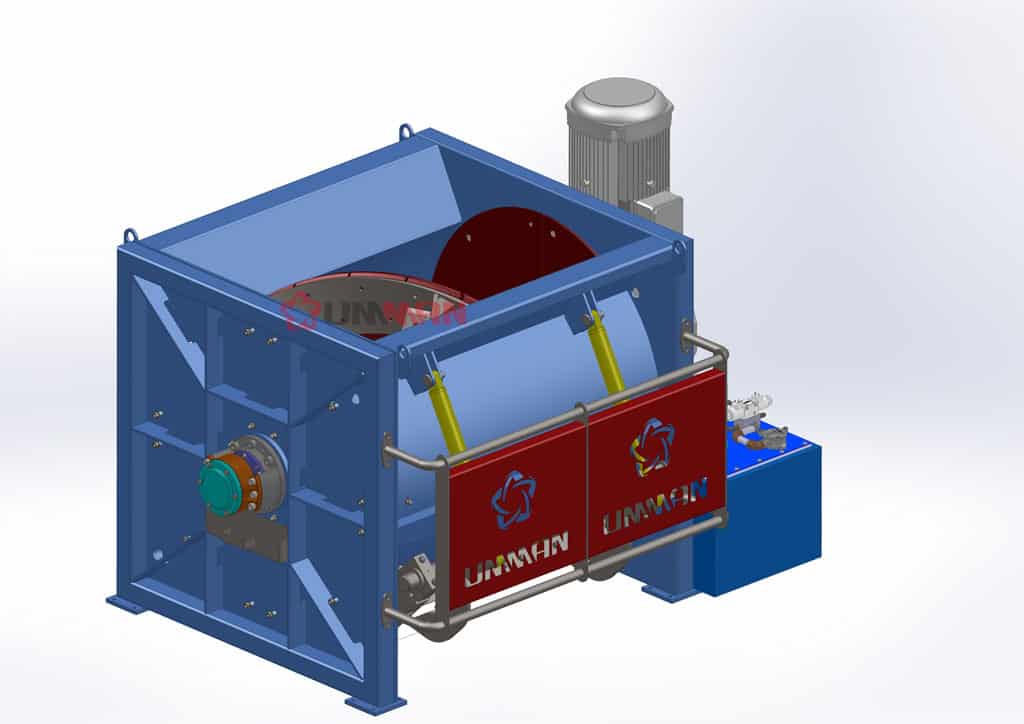

The most important feature of twin shaft concrete mixers is the provision of a homogenized mixture in mass concrete casting compared to other types. In concrete mixers, the full contact of cement with aggregate is ensured as soon as possible for increased efficiency of the system and low water cement ratios for minimum energy consumption. This is best done in twin shaft concrete mixers. In addition, as with other mixers, the automatic lubrication system in concrete mixers increases the life of mixers. For these reasons, UMMAN uses double shaft concrete mixers in its large capacity concrete plants.

Optional equipment such as 2 or more discharge covers, special design for RCC production, high pressure mixer internal washing, humidity and temperature sensor etc. are installed on UMMAN twin shaft mixers offered in a wide capacity range from 1 m3 concrete to 4 m3 concrete production according to the project and application requirements. It offers a comprehensive and wide range of high-performance solutions to suit all the concrete needs of customers. Our twin shaft mixers are two horizontally mounted mixer shafts and are the ideal mixer type suitable for concrete mixing time and quality. It is preferred by companies that want medium and high capacity.

FEATURES

The design of twin shaft mixers greatly reduces the likelihood of failure. It brings maintenance and repair convenience as it is manufactured with newer technology. Twin shaft mixer allows the concrete to accumulate between the two shafts while working. This significantly reduces the amount of wear between the mixing arms and the bottom liner. In single shaft mixers, it is mandatory to use cast iron or steel plate to increase wear resistance. This increases the cost. Twin shaft mixers provide movement in both radial and axial directions. Thus, it achieves effective results even at lower speed compared to single shaft mixers. For this reason, it is much more advantageous to invest in twin shaft mixers instead of single shaft mixers.

ADVANTAGES

Large chamber to optimize loading procedures

Our high capacity loading hoppers shorten the loading period and offer a more agile and efficient system. We also prevent possible failures by preventing jams caused by material accumulation in smaller chambers.

Central lubrication of drum cylinders

We all know the importance of lubricating a machine with different elements that rotate according to the position of fixed parts like a concrete mixer. The convenience of having a single greasing point attached to all elements used for such purposes and ease of greasing will greatly facilitate this vital task to achieve optimum performance and maximum durability of the machine.

Technıcıal Specıfıcatıons

| SPECIFICATIONS | UNIT | VALUE |

|---|---|---|

| MixerCapacity | m³/h | 4 |

| DryFillingCapacity | Litre | 6000 |

| CompactedConcrete | Litre | 4000 |

| Motor power | kW | 2×75 |

| Electric Delta Connection | 380V/50Hz | |

| Motor Rotation | rpm | 1450 |

| Mixing Arms | Qty | 20 |

| Side Pallets | Qty | 2+2 |

| Hydraulic System Engine Power | kW | 2.2 |

| Mixing Arm Rotaiton | rpm | 24.3 |

| Weight | kg | 16000 |

| SPECIFICATIONS | UNIT | VALUE |

|---|---|---|

| MixerCapacity | m³/h | 3 |

| DryFillingCapacity | Litre | 4000 |

| CompactedConcrete | Litre | 3000 |

| Motor power | kW | 2×55 |

| Electric Delta Connection | 380V/50Hz | |

| Motor Rotation | rpm | 1450 |

| Mixing Arms | Qty | 16 |

| Side Pallets | Qty | 2+2 |

| Hydraulic System Engine Power | kW | 2.2 |

| Mixing Arm Rotaiton | rpm | 24.3 |

| Weight | kg | 10500 |

| SPECIFICATIONS | UNIT | VALUE |

|---|---|---|

| MixerCapacity | m³/h | 2 |

| DryFillingCapacity | Litre | 3000 |

| CompactedConcrete | Litre | 2000 |

| Motor power | kW | 2×37 |

| Electric Delta Connection | 380V/50Hz | |

| Motor Rotation | rpm | 1450 |

| Mixing Arms | Qty | 12 |

| Side Pallets | Qty | 2+2 |

| Hydraulic System Engine Power | kW | 2.2 |

| Mixing Arm Rotaiton | rpm | 24.3 |

| Weight | kg | 6500 |

| SPECIFICATIONS | UNIT | VALUE |

|---|---|---|

| MixerCapacity | m³/h | 1 |

| DryFillingCapacity | Liter | 1500 |

| CompactedConcrete | Liter | 1000 |

| Motor power | kW | 2×22 |

| Electric Delta Connection | 380V/50Hz | |

| Motor Rotation | rpm | 1450 |

| Mixing Arms | Qty | 8 |

| Side Pallets | Qty | 2+2 |

| Hydraulic System Engine Power | kW | 2.2 |

| Mixing Arm Rotaiton | rpm | 24.3 |

| Weight | kg | 5000 |